Explain Why the Difference Between Engineering Strain and True Strain

30 and 29 on. Without getting into all the math the engineering strain utilizes the initial length of the specimen in the calculation the true strain utilizes the instantaneous length of the specimen.

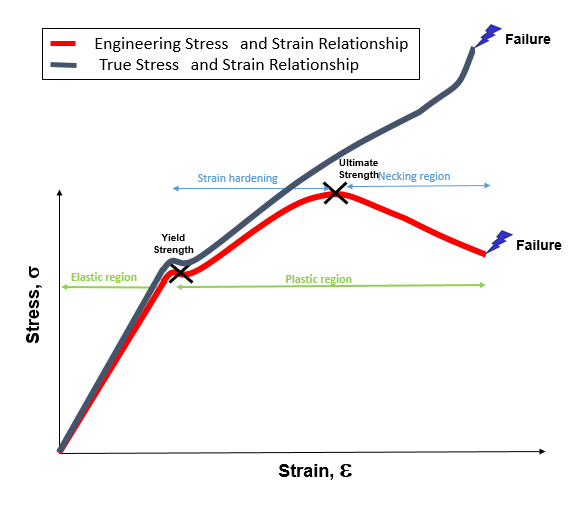

Engineering Stress Strain Vs True Stress Strain Yasin Capar

The difference between the engineering and true strains becomes larger because of the way the strains are defined respectively as can be seen by inspecting Engineering strain or normal strain.

. According to definitions Engineering strain e final length - initial lengthinitial length final length initial length - 1. View the full answer. Quick Engineering stress is the applied load divided by the original cross-sectional area of a material.

Ln ln 1 0 0 0 A A l l dl l l l This. Show that using engineering strains the strain for each step cannot be added to obtain. 22 and 27 on p.

Explain why the difference between engineering strain and true strain becomes larger as strain increases. This is true for both tensile and compressive strains. A strip of metal is originally 15 m long.

MANI B answered on January 31 2022 5 Ratings 14 Votes ANSWERS. Is this phenomenon thru for both tensile and compressive strains. σ s 1e ε ln 1e Where s and e are the engineering stress and strain respectively and σ and ε are the true.

Also note that the elongation is a function of gage length and increases with gage length. Mechanical Engineering questions and answers. Explain why the difference between engineering strain and true strain becomes larger as strain increases.

Whereas Engineering strains are based on the Virgin Original state of the material. 0 0 l l l e True strain. 22 Explain if it is possible for stress-strain curves in ten-sion tests to reach 0 elongation as the gage length is.

Also known as nominal stress. The relationships between engineering values and true values are. Sile and compressive strains.

Show that the total true strain is the sum of the true strains in each step that is that the strains are additive. First to a length of 175 m then to 20 m and finally to 30 m. Answer 1 of 7.

3 The difference between the engineering and true strains becomes larger because of the way the strains are defined respectively as can be seen by inspecting and Using the same scale for stress we note that the tensile true-stress-true-s. Explain why the difference between engineering strain and true strain be- comes larger as strain increases. Conversely since true strain is calculated by integrating the strain over the entire test it is larger than engineering strain for the same value of displacement.

Strain true and engineering and true fracture strain can be determined. Mechanical Engineering questions and answers. In circle grid analysis engineering strain is the percent expansion of the circle compared to the initial diameter of the circle.

Explain why the difference between engineering strain and true strain becomes larger as strain increases. This is true for both tensile and com pressive strains. True strain equals the natural log of the quotient of current length over the original length as given by Eq4.

There is no decrease in true stress during the necking phase. Explain why the difference between engineering strain and true strain becomes larger as strain increases. Plasticity needs information on the previous state of the body hence true strains are preferred.

Engineering strain is the amount that a material deforms per unit length in a tensile test. Explain why the difference between engineering strain and true strain be- comes larger as strain. Thus we cannot calculate the per-cent elongation of the specimen.

Is this phenomenon true for both tensile and compressive strains. True strain equals the natural log of the quotient of current length over the original length. Is this phenomenon true for both tensile and compressive strains.

True strain equals the natural log of the quotient of current length over the original length. True stress is the applied load divided by the actual cross-sectional area the changing area with respect to time of the specimen at that load Engineering strain is the amount that a material deforms per unit length in a tensile test. Show transcribed image text Expert Answer Answer.

In both cases of tension and compression the difference increases as strain increases. Does this difference occur for both tensile and compressive strains. The difference between the engineering and true strains becomes larger because of the way the strains are defined respectively as can be seen by inspecting Eqs.

Is this phenomenon true for. Engineering strain is the amount that a material deforms per unit length in a tensile test. Also known as nominal strain.

It is stretched in three steps. Explain why the difference between engineering strain and true strain becomes larger as strain increases. The difference between the engineering and true strains becomes larger because of the way the strains are defined True strain is however always larger than engineering strain.

Explain why the difference between engineering strain and true strain becomes larger as strain increases. The difference between the engineering and true strains becomes larger because of the way the strains are defined respectively as can be seen by inspecting Eqs. 30 and 29 on p.

The answer lies in the fact that the definitions of engineering strain and true strain are different the latter being based on the actual or instantaneous dimensions as can be seen in Eqs. Mechanical Engineering questions and answers. If a material that strain hardens is tested.

24 Using the same scale for stress we note that the tensile true-stress-true-strain.

What Is The Difference Betweem True Stress And Flow Stress

Difference Between Engineering Stress And True Stress Youtube

Engineering Stress Strain Vs True Stress Strain Ahss Guidelines

No comments for "Explain Why the Difference Between Engineering Strain and True Strain"

Post a Comment